From Design to Shipping: Sheet Metal Innovation at Tecnofutura.

Precision Machining and Fiber Laser Cutting in Pavia

Tecnofutura Srl is the reference mechanical workshop, active since 1990 in Valle Salimbene, Pavia, and specialized in

precision machining on all types of sheet metal and pipesWith over thirty years of experience, we have been able to combine the solid tradition of mechanical carpentry with the use of

cutting-edge technologies, like the modern

Fiber Laser Cutting and combined laser-tube machining. Our headquarters spans over 5,000 square meters of industrial warehouses and employs a team of over 40 professionals, including specialized engineers and technicians. We offer a comprehensive and integrated service that covers the entire production cycle: from CAD/CAM design to complex machining (cutting, punching, bending, welding), all the way to surface treatments and polyurethane foaming. Tecnofutura is not just a supplier, but a true technological partner for companies requiring the highest quality and precision sheet metal components.

Experience and Tools: The Complete Cycle of Precision Mechanical Machining

Thanks to a consolidated experience in the sector, active since 1990, and to a constantly updated fleet of machines,

Technofuture is able to perform

precision mechanical machining on any type of sheet metal and tube. Our expertise covers the entire production cycle, starting from

Fiber Laser Cutting and from the combined cutting and punching processes. We then move on to the

folding of the highest quality and

welding qualified, including specific processing of copper and aluminum rolled bars. Our "turnkey" service continues with essential interior finishes, such as

powder coating and the specialist

polyurethane foaming for insulation and protection. Furthermore, we guarantee access to complex external surface treatments, such as

galvanizing And

tinning, thanks to a consolidated and profitable network of trusted suppliers. This combination of in-house experience and external partnerships allows us to offer certified, high-quality end results.

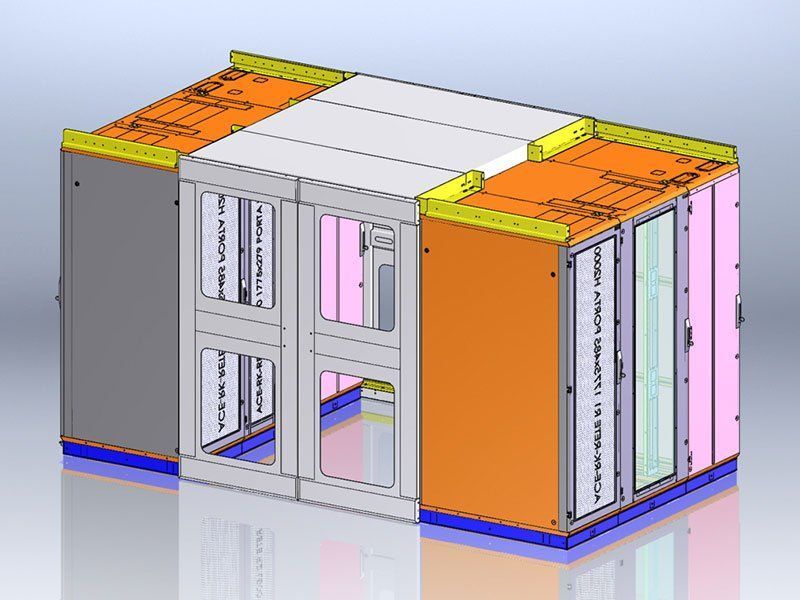

Machine Park 4.0: Excellence in Fiber Laser Cutting and Bending

Technofuture uses a technologically advanced fleet of machines to guarantee

high-precision manufacturing and high productivity. The beating heart of our workshop is represented by the modern centre

Laser cutting Bystronic BTL 3015 and the Adige BLM LC5 fiber laser-tube combination. These cutting-edge equipment allow us to operate 24 hours a day, performing impeccable processing on sheet metal and tubes of various materials, including iron,

stainless steel, aluminum, copper and sendzimir sheets. For the operations of

punching We have the Rainer CNC 2500 punching machine and the Euromac punching machine, guaranteeing versatility and detail. Furthermore, to consolidate our leadership in the

foldingWe recently expanded our department with the purchase of a second Salvagnini P2XE 2500 panel bender. This ongoing investment in cutting-edge technology and machinery ensures our customers not only pinpoint precision, but also the efficiency and production capacity needed to handle large volumes of work.

Our customers, our strength

For over 30 years we have been collaborating with leading companies in various industrial sectors.

Every project is an opportunity for us to grow alongside our clients, offering customized solutions and consistent quality.

Some of our clients

- Companies in the electromechanical sector

- Companies in the air conditioning and refrigeration sector

- Technical and commercial furnishing (shops, museums, jewelry displays)

- Companies active in industrial extraction and electrical systems

What they say about us

- “TecnoFutura is a reliable partner, with fast turnaround times and consistently high quality.”

— Client in the electromechanical sector - “Thanks to their cutting-edge technologies, we have improved precision and reduced production times.”

— Client in the industrial air conditioning sector - “The difference lies in the people: professional, available, and always solution-oriented.”

— Client in the technical furniture sector

Want to become one of our partners? Contact us to start a collaboration.

Turn your idea into a precision product!

Contact us now for a consultation or request your personalized quote now.